You depend on stainless steel marine fittings to make your boat safe and sturdy. These fittings use special steel that does not get damaged easily by saltwater, air, or small living things. Saltwater works like an electrolyte and makes metal break down faster, especially when different metals touch. Stainless steel keeps your boat safe by using coatings and barriers. These stop water and bad things from touching the metal. Picking marine-grade stainless steel helps you stop rust. It also helps your boat last a long time and work well.

Stainless Steel Marine Fittings: Key Properties

Corrosion Resistance

Boats need hardware that can handle saltwater, rain, and sun. Stainless steel marine fittings from Kaitu Fitting protect your boat from these things. The steel has special chemicals inside it. Marine-grade stainless steel has chromium, nickel, and molybdenum. These chemicals help stop rust and pitting. Molybdenum is very good at fighting damage from salt and chloride.

- Marine-grade stainless steel works well in tough places.

- Chromium makes a thin layer that blocks water and air.

- Nickel makes the steel strong and shiny.

- Molybdenum helps stop saltwater from causing rust.

If you use 316 stainless steel, you get even better protection. This steel has 2-3% molybdenum. It keeps your fittings safe from pitting and crevice corrosion. That is why 316 stainless steel is best for boat parts and docks. It lasts longer than 304 stainless steel. 304 is better for freshwater or indoor use.

Strength and Durability

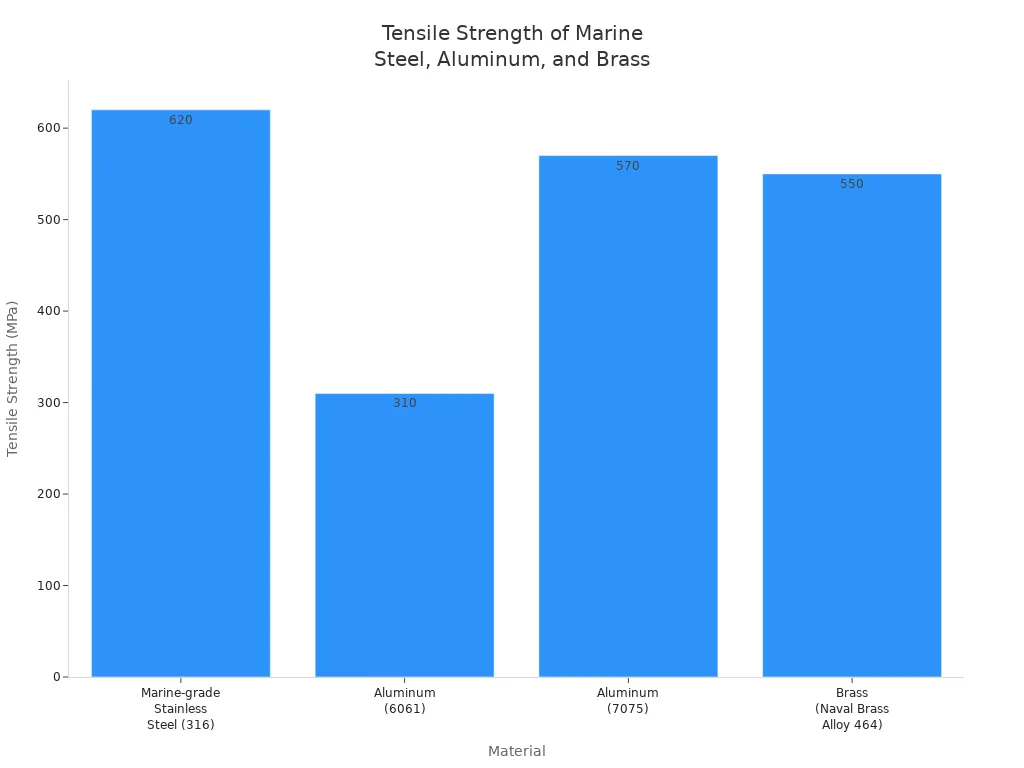

Boat hardware needs to be strong under heavy weight. Stainless steel marine fittings have high tensile strength. They can handle pulling, twisting, and bending. They do not break easily. Here is how marine-grade stainless steel compares to other metals:

| Material | Tensile Strength (MPa) |

|---|---|

| Marine-grade Stainless Steel (316) | 620 |

| Aluminum (6061) | 310 |

| Aluminum (7075) | 570 |

| Brass (Naval Brass Alloy 464) | 550 |

| Brass (General) | 300-600 |

| Aluminum (General) | 90-570 |

Stainless steel marine fittings do not just avoid breaking. They last a long time. The steel makes a protective layer. This is called passivation. The layer keeps out water and air. Your fittings do not rust or wear out fast. You save money because you do not replace parts often. If you pick 316 stainless steel, you get even more durability. It works best in salty places. For more comparisons, see our guide on brass vs. stainless steel.

Tip: Using stainless steel marine fittings helps your boat gear last longer. It also keeps you safer when you are on the water.

Appearance and Maintenance

You want your boat to look nice and work well. Stainless steel marine fittings keep their shine and smooth look for years. They do not stain or change color easily. To keep them looking good, follow these steps:

- Rinse fittings with freshwater often to remove salt.

- Do not let saltwater dry on the fittings.

- Make sure fittings have good drainage and airflow.

Stainless steel marine fittings need less care than other metals. You do not need to paint or coat them. They can last over 50 years without extra work. Other metals, like brass or carbon steel, need more cleaning or new coatings. Stainless steel fittings also meet strict rules, like ABS certification. This means they are safe and reliable for boats.

| Certification | Description |

|---|---|

| ABS Certification | Makes sure fittings follow ABS rules for materials, design, and making in marine and offshore jobs. |

Makers test these fittings before selling them. They check the chemicals, test the strength, and look for hidden problems. This way, you know your stainless steel marine fittings will work well and last a long time.

Types of Stainless Steel Marine Fittings

304 vs. 316 Grades

When you pick stainless steel marine fittings, you see two main grades. These are 304 and 316. Both look almost the same, but they do not act the same in tough places. 304 stainless steel is used a lot because it does not rust or stain easily. But 304 does not do well in salty or wet spots. Saltwater can make small holes and cause rust after some time.

316 stainless steel gives better protection. This grade has molybdenum. Molybdenum helps stop rust from salt, water, and chemicals. You find 316 on boats, docks, and buildings near the sea. It fights off pitting from chloride, so your fittings last longer in the ocean. If you use 304, keep it for dry or indoor places. For boats, 316 is the best pick.

| Grade | Main Alloying Elements | Corrosion Resistance | Best Use |

|---|---|---|---|

| 304 | Chromium, Nickel | Good | Indoor, dry areas |

| 316 | Chromium, Nickel, Molybdenum | Excellent (especially against saltwater) | Marine, coastal, chemical environments |

Tip: Choose 316 stainless steel for your boat. It lasts longer and does not rust in salty water.

Marine-Grade Hardware

You need marine-grade hardware if your boat faces rough ocean weather. These fittings use special stainless steel grades. The most common is 316, but there is also 316L. The “L” means low carbon. This helps when welding and keeps the metal strong after joining.

- Grade 316 stainless steel is best for saltwater.

- Grade 316L is almost the same but is easier to weld.

- Grade 310 is used for very hot or acidic places.

Marine-grade stainless steel marine fittings have molybdenum, usually 2-3%. This makes them strong against pitting and crevice rust. Your boat stays safe even with waves, salt, and changing weather. Regular stainless steel hardware does not protect as well. If you use marine-grade fittings from Kaitu Fitting, you keep your boat safe and save money on repairs.

Applications of Stainless Steel Marine Fittings

Stainless steel marine fittings play a key role in many parts of your boat. You see them on decks, in rigging, and in safety systems. These fittings help your boat stay strong, safe, and ready for any challenge on the water.

Deck Hardware (Cleats, Chocks)

You use deck hardware every time you tie your boat to a dock or secure a line. Cleats and chocks made from stainless steel give you peace of mind. They hold your ropes and lines tight, even when the weather gets rough. You can trust these fittings because they do not rust or break easily.

Here is a table showing common types of deck hardware and their functions:

| Type of Hardware | Material Used | Function |

|---|---|---|

| 2” Square Posts | 2205 Stainless Steel | Supports railings and keeps people safe on deck. |

| ¼” Rods Infill | 2205 Stainless Steel | Adds safety and looks good in railing systems. |

| 1” x 2” Handrail | 2205 Stainless Steel | Gives you a strong grip and helps prevent falls. |

| Deck Elite Hidden Deck Fasteners | Stainless Steel 316 | Holds deck boards tight and makes the deck look smooth. |

You want your cleats and chocks to work well every time. Here is why stainless steel makes a difference:

- Strong, reliable connections keep your boat safe at the dock.

- Smooth operation means you can tie up quickly in emergencies.

- The fittings keep your boat’s structure strong, even in storms.

- Stainless steel resists rust, so you do not worry about failures.

- You can use these fittings on small boats or large yachts.

Tip: Always check your cleats and chocks for signs of wear. Replace them if you see rust or damage. Good hardware keeps you and your boat safe.

Rigging and Connectors (Shackles, Tubes)

Rigging holds your boat together and helps you control the sails. You find many types of rigging and connectors made from stainless steel. These include thimbles, wire ropes, and shackles. You use them to support the mast, attach sails, and connect important parts.

Some common rigging parts are:

- Stainless steel thimbles

- Sailmakers thimbles

- Wire ropes (1 x 19, 7 x 19, 7 x 7, all Grade 316)

- Shackles and turnbuckles

Standing rigging uses stainless steel wire to keep the mast steady. Grade 316 wire works best because it does not rust in saltwater. You also see stainless steel tubes used for rails and handholds. These tubes give your boat strength and help keep passengers safe.

- Marine stainless steel tubes resist corrosion and stay strong for years.

- You need the right grade for safety and long life.

- Shackles and fasteners made from stainless steel handle heavy loads without breaking.

Note: Always pick marine-grade stainless steel for rigging. It keeps your boat safe and ready for any trip.

Safety and Utility Uses

You depend on stainless steel marine fittings for safety every time you step on your boat or walk on a dock. Cleats are one of the most important safety features. If a cleat fails, your boat could drift away or someone could get hurt. Quality matters more than price when it comes to safety.

“Cleats are probably the most visible marine hardware, and they’re also one of the most critical from a safety standpoint. A failed cleat can result in a lost boat or serious injury, which is why quality matters more than price.”

You also use stainless steel fittings for utility jobs and emergency repairs. Here are some examples:

| Fitting Type | Benefits |

|---|---|

| Stainless Steel Cast Fittings | Resist corrosion, work well for hulls, decks, and plumbing. |

| Stainless Steel Nipples | Last long in plumbing and fluid systems. |

| Stainless Steel Flanges | Make strong, rust-free connections in marine systems. |

When you build docks or coastal structures, you want to use larger, stronger fasteners. Through-bolts and double hardware give you extra safety. Grade 316 stainless steel is the best choice for saltwater. It keeps your equipment strong and lowers the risk of failure.

- Oversize fasteners give you more holding power.

- Through-bolts work better than screws for important connections.

- Double up on hardware for extra safety.

You keep your boat and dock safe by choosing the right fittings and checking them often. Stainless steel marine fittings help you avoid costly repairs and keep everyone safe on the water.

Care and Maintenance

Cleaning and Inspection

You keep your boat safe by cleaning your stainless steel marine fittings often. Use soap to wash away dirt. Wax helps block water and salt. Polish makes the metal smooth and removes stains. Chemical cleaners can help with rust, but always use a soft towel or sponge so you do not scratch the metal. After cleaning, rinse with fresh water to get rid of salt and other bad stuff. If you want a deep clean, use a product like Super Stainless Cleaner. Put it on with a soft cloth, wait 45 minutes, then rinse well. Cleaning often stops stains and rust before they start.

Check your fittings before every long trip. Look for wear, leaks, or rust. Take down the mast every few years to check fittings close up. Checking often helps you find problems early and keeps your boat safe.

Preventing Corrosion

Saltwater and chlorides can hurt metal fast. You protect your fittings by rinsing them with fresh water after each trip in saltwater. Remove any marine growth so rust does not start in small spots. Clean and fix damaged fittings right away. Use polish often for extra protection. Do not use cleaners with chlorides or acids because they can damage the metal’s protective layer. In coastal places, use marine-grade paint or epoxy for more safety. You can also use sacrificial anodes or special current systems to protect parts under water.

| Environment | Protection Needed |

|---|---|

| Coastal (within 3,000 ft) | Extra protection from rust |

| Industrial | Clean and check fittings often |

Replacement Tips

You need to know when to change a fitting. Watch for stains that look like a barber pole, white powder, burn marks, or blue spots. These show heat or electrical damage. If you see damage to wires, change the fitting right away.

To change a fitting safely, use an impact driver to tighten nuts but do not make them too tight. Take off the old fitting and clean the spot with acetone. Put on marine sealant before you add the new fitting. Use a step wrench and adjustable wrench to tighten from outside the boat. Wipe away extra sealant and make sure bolt heads are clear. For spots under water, use vinyl ester filler to make it smooth.

Tip: Taking care of your fittings and fixing problems fast keeps your boat safe and strong.

You get lots of good things when you use stainless steel marine fittings on your boat. The table below shows how these fittings help you as time goes by:

| Benefit | Description |

|---|---|

| Durability and Longevity | Stainless steel does not rust easily, so your fittings last longer in saltwater. |

| High Strength | This material can handle strong sun and rough marine weather. |

| Investment in Longevity | You save money because you do not have to buy new parts often. |

| Temperature Resistance | Fittings stay strong even when it is hot or cold outside. |

| Better Safety and Functionality | Your boat stays safe and works well, even when things get tough. |

When you pick fittings from Kaitu Fitting, choose the right grade for your boat:

- 304 stainless steel is best for parts inside or in freshwater.

- 316 stainless steel is great for hinges, propeller shafts, and deck fittings in saltwater.

Keep your boat safe by washing fittings after saltwater trips. Check for damage and fix problems fast. If you take care of your equipment, it will last longer and keep you safe on the water. For more details or custom needs, contact us.

FAQ

What is the best way to clean stainless steel marine fittings?

You should rinse your fittings with fresh water after each trip. Use mild soap and a soft cloth to remove dirt. Dry the fittings well. Avoid harsh chemicals. This keeps your fittings shiny and strong.

How do I know if a fitting needs to be replaced?

Look for rust spots, cracks, or loose parts. If you see white powder or blue stains, the fitting may be damaged. Replace any fitting that looks worn or unsafe. Safety comes first.

Can I use 304 stainless steel on my boat?

You can use 304 stainless steel for indoor or freshwater parts. For saltwater or outdoor use, choose 316 stainless steel. It resists rust better and lasts longer in harsh marine environments.

Why do marine fittings cost more than regular hardware?

Marine fittings use special stainless steel that fights rust and lasts longer. Makers test these parts for strength and safety. You pay more, but you get better protection for your boat.